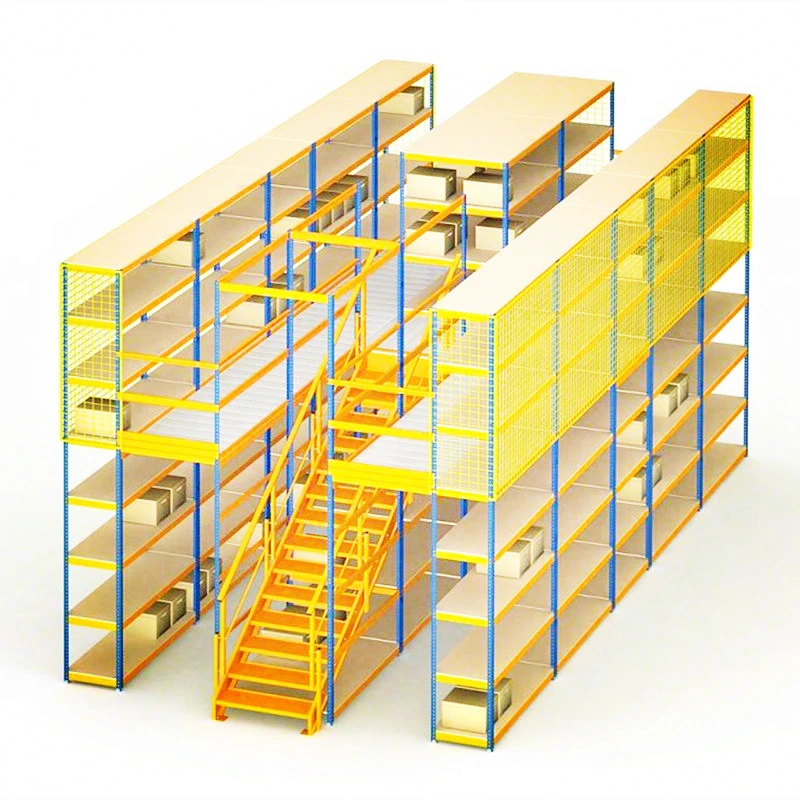

Warehouse Storage Multi Level Mezzanine Racking

1. Product Description: Warehouse Storage Multi Level Mezzanine Racking, Manual pick can reach up to 2 meters only, in o;

Basic Info

| Model NO. | MF 100 |

| Usage | Industrial, Warehouse Rack |

| Material | Steel |

| Structure | Shelf |

| Type | Multi-Level Racking |

| Mobility | Adjustable |

| Height | 0-5m |

| Weight | 150-500kg |

| Closed | Semi-closed |

| Development | Conventional |

| Serviceability | Common Use |

| Mezzanine Floor | Steel Grating or Plate |

| Floor Loading | 300-500kg/M2 |

| Maxium Height | 4.5-7.0m |

| Finish | Powder Coated |

| Transport Package | Packed in Bundles on Pallets and Wraped in Film |

| Specification | upright 1.5mm, shelves 0.8mm |

| Trademark | CALIN |

| Origin | Jiangsu, China |

| HS Code | 73089000 |

| Production Capacity | 20, 000 Tons Per Year |

Product Description

1. Product Description:Warehouse Storage Multi Level Mezzanine Racking, Manual pick can reach up to 2 meters only, in order to fully utilize the head room space, shelving with raised floor is developed to improve the pick height problem. The shelving system can be built to 1+ 1, 2 tiers or above to double your warehouse capacity. The upper floor is easily reached by staircase, elevator, and slide way or loading platform.

It is good for the storage of small items with split carton picking, in some occasion the system can provide with parts container and transport containers to meet customer needs. The fast moving items can arrange to store in the ground floor while the other items can be stored in the upper floor according to priority sequence.

Warehouse Storage Multi Level Mezzanine Racking, Its standard is normally the same as Long Span racking, but in most cases it is made to measure. The uniform distributed load is from 100 to 300kg per shelf, the floor loading is 500kg/m2 U.D.L. We also carry different types of floors to meet individual requirements, such as steel decking, wood decking, galvanized industrial steel decking and galvanized grating floor, the normal loading for the mezzanine is around 400-500 kg/m2

2. Steel Grating for the Mezzanine Floor:

Warehouse Storage Multi Level Mezzanine Racking, This steel grating is manufactured by cross inserted steel strips with the joint spot welded. The most popular is the 30*30 spacing and 11*44 spacing. Different thickness is offered to accommodate any load rating requirements. This method offer air ventilation under Mezzanine floor and adapt to fire fighter safety regulations.

3. The basic components

Upright:

The upright is 60mm width, which has the similar structure with pallet rack frames. Horizontal and diagonal braces are fitted to the lower and upper part to ensure frame rigidity. Bolted base plates are fitted to each frame, dependent on designed capacity.

Step Beam

They are adjustable on vertical pitch of 50mm or 75mm. Each beam has a step of 24-28mm for fitting of steel shelves, and an integral safety lock is fixed to prevent accidental removal of step beams. Beam load capacity is based on your requirements.

Steel shelves

Cold rolled steel sheets are used to make the steel shelves. Normally the material thickness can be 0.6mm to 0.8mm for SPCC. Underneath the shelves, reinforced bars are spot welded to offer more loading capacity.

The finish of all painted parts is an Epoxy-powder coating polymerized at 180 °C.

The standard colors are RAL 5015 (=blue) and RAL 7035 (=light gray). Shleves can also be galvanized finishing. Special colors are available on request.

4. Advantages and Key benefits·

Complies with international norms and regulations

· Wide range of basic components for storage of all pallet sizes and weights.

· Many standard accessories to meet every storage need you can imagine

· Computer aided design ensuring the best solution for every application, including static calculations

· Rigid and stable construction

· High quality of finish

· Easy and quick installation

· Mass volume production to offer very cost effective products

5. Factory Production:

6. RFQ documents: Before you send us your Requirement For Quotation, please prepare the following information:

Warehouse layout CAD drawings if available.

Carton box size, width, depth and height.

Loading weight per box.

Clear height of the warehouse

Required line items to be stored.

Your intra logistic flow within the warehouse.

mateail handling equipment informaiton such as picking trolley, mobile ladders, etc.

You may also like

Send inquiry

Send now